Boat Cover Snaps

Which Ones Should You Use?

This article takes an up-close look at the different boat cover snaps. There are different types of snaps for different applications, depending upon angles and wind factors.

Don't be afraid of replacing your existing snaps. This is a fairly straightforward DIY boat cover snaps repair job, but you should read the following information carefully to familiarize yourself with each type of fastener.

Boat Cover Snaps: Button Fasteners

The most common snaps used on canvas boat covers are glove button fasteners or durable-type snaps. Dot fasteners and Fasnap are two common names.

They consist of a button and socket which are crimped together and become the female snap in the canvas. Then you have the eyelet and stud that are crimped together and form the male snap in the canvas.

Windshield Clip

Windshield ClipNote: Boat owners assume that all snaps put on a boat are stainless steel, but actually only a few are. The boat cover snaps pictured above do come in stainless steel. They also come in nickel-plated brass which many shops still use and this is not necessarily a problem.

Stainless steel holds its finish better and is stronger than the brass crimp, but when seated properly into the canvas the nickel/brass does a fine job as well.

What you don't want to see is the snap socket or stud spinning loosely on the material. I don't mean where you grab it and turn it, what I mean is when you can use the tip of your index finger to spin it in a circle and it moves freely. A snug crimp puts less strain on the snap and the material.

Boat Cover Snaps: YKK Snads

YKK manufacturer of marine zippers has introduced a new line of boat cover snaps that are domed plastic with adhesive backs. They are compatible with all brands of button or durable snaps of the same size.

I am excited about Snads since there are times when you just don't want to drill a hole into your boat, and for this application they can't be beaten.

Clean properly and then peel and stick. It doesn't get any easier than that. The high-tech VHB adhesive is strong and lasts a long time, and there are so many great reasons to try Snads if you're planning a DIY boat cover repair.

Be sure to check out Snads in our store as companions to EZ-Xtend Boat Zippers for re-aligning snaps already in the boat.

Snads Available in White and Black

Snads Available in White and BlackBoat Cover Snaps: Screw Studs

Screw studs basically speak for themselves, but look at the sizes and lengths.

These are male companions to the button fasteners. Note the #10 screw stud above. Ideal for enlarged holes that won't hold a #8 screw.

What Are Directional Fasteners?

When Do You Use Them?

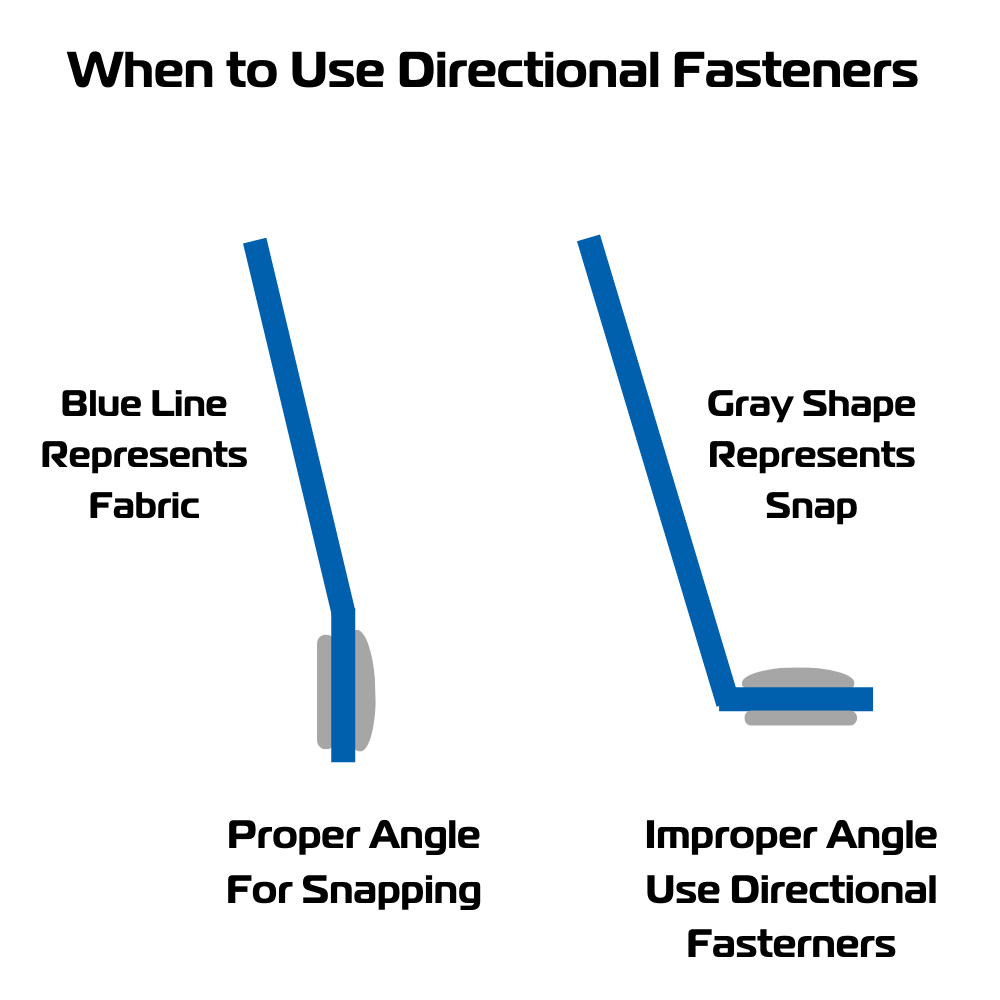

In order for button fasteners to stay snapped on a boat, the angle

cannot be too sharp. Conventional boat cover snaps work best when the

base is on the same plane as the fabric itself.

If the canvas is pulling too hard at the wrong angle, the snap will unsnap itself with the slightest pressure. Since there are plenty of odd angles on boats, this happens frequently. It can be a real challenge for boat covers to stay snapped.

With this in mind, there are several boat cover snaps that work well under stressed conditions. These types of snaps are called directional fasteners.

Here are the three most common types of directional fasteners used on boat enclosures and boat covers:

- Pull-the-Dot

- Curtain Fasteners, aka Twist Fasteners

- Lift-The-Dot

Boat Cover Snaps: Pull-the-Dot Snaps

The trickiest of all fasteners

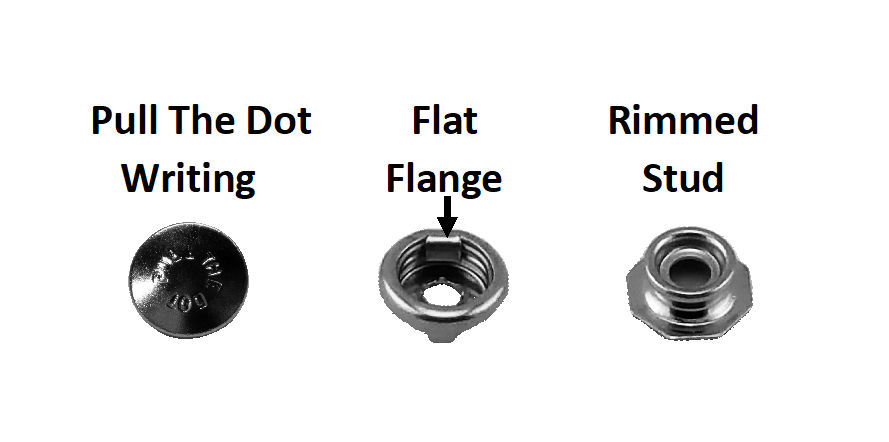

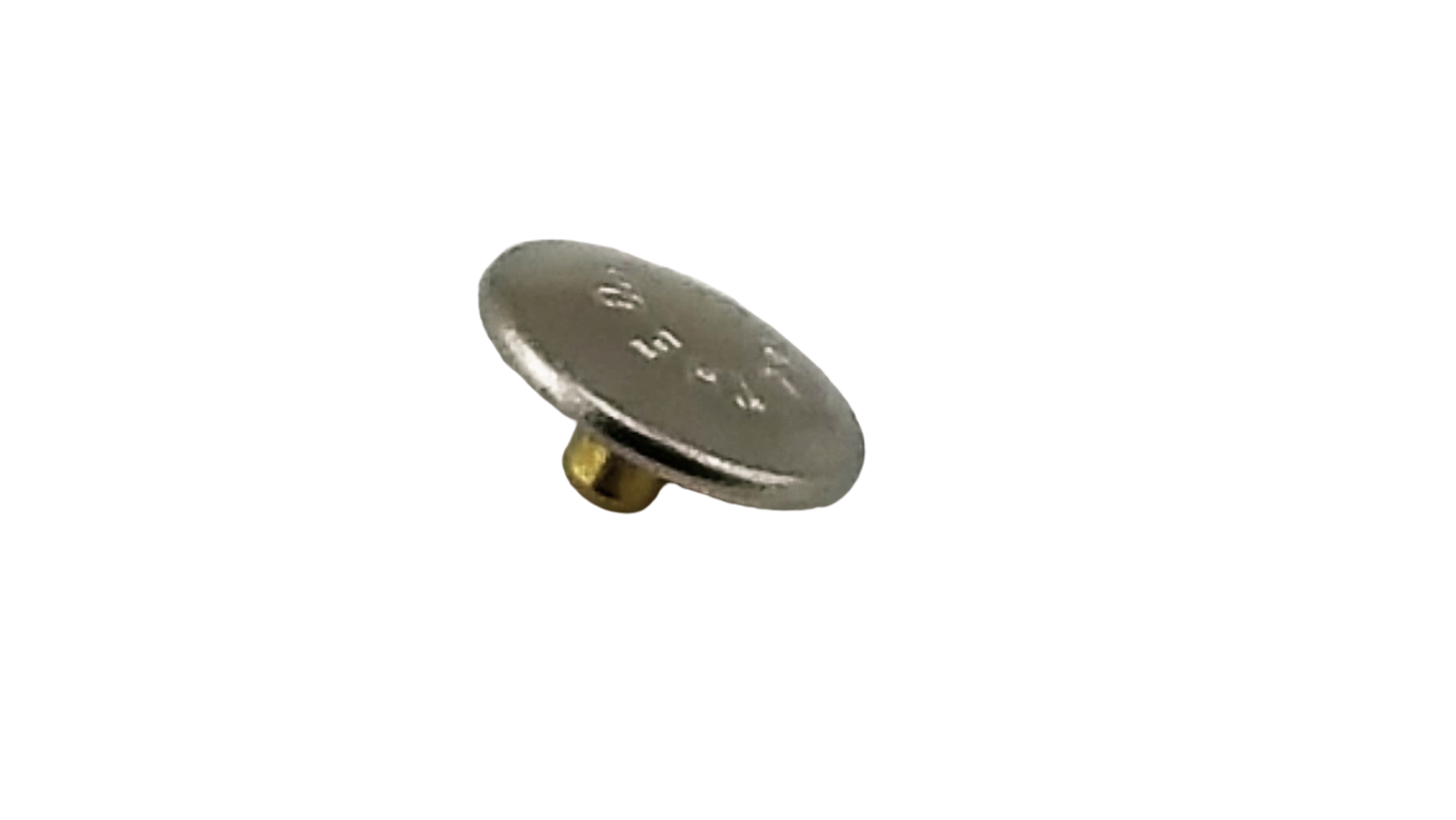

Even though they look like glove buttons, note the words Pull the Dot on the top of the snap button. When you see these words you will know that they only come off in one direction.

Look closely at the socket on the second picture. You will see a little flat surface on the inside of the flange. This little flat surface is designed to hook over the edge of the flange on the third picture showing the stud.

Once the snap is snapped, you can try and lift from the direction of the flat surface and the snap will not lift off of the stud. This snap is convenient in areas where you'd need a very flat directional fastener to keep from hurting yourself on the base protruding from the boat.

This is a very confusing snap for people because it looks like any other snap. Boaters will tug and jerk on it and still not be able to remove it, and this sometimes results in a tear of their canvas.

They also tend to be become a little sticky as they age and need lubrication to keep this from happening. Although a little aggravating, they do come in handy if you know how to use them.

Pull-the-Dot Button Pull-the-Dot Button |

Pull-the-Dot Socket Pull-the-Dot Socket |

Pull-the-Dot Stud Pull-the-Dot Stud |

Pull-the-Dot Screw Stud 3/8" Pull-the-Dot Screw Stud 3/8" |

Pull-the-Dot Screw Stud 5/8" Pull-the-Dot Screw Stud 5/8" |

Eyelets Used for Pull-the-Dot Eyelets Used for Pull-the-Dot |

Boat Cover Snaps: Curtain Fasteners

Curtain Fasteners are another type of directional fastener, commonly called twist fastener or turnbutton fastener. This fastener is a favorite among boaters. It's easy to use and has a low failure rate.

Curtain Fasteners:

The first two pictures above are the male bases for the turnbutton curtain fastener.

I have pictured only the 2-screw stud bases, since I never use the single screw bases. In my opinion, two screws are better than one.

Note how one base has a longer shank than the other. The short shank is actually so short you can sometimes have difficulty turning the top once the female eyelet is on it. For me, the long shank curtain fasteners are the way to go.

The third picture is another style of curtain fastener. The pronged eyelet is installed in the canvas by first punching a hole. The hole has four small prong holes surrounding a larger center hole, just as the shape of the eyelet itself.

The eyelet goes on the outside of the canvas and the backing plate goes over the prongs on the back side of the canvas. There are two types of backing plates that can go on the back side of the canvas where the prongs crimp down on top of the washer.

Note the washer with the holes for the prongs. I like this style better than the flat smooth washer, as it's more secure when the prongs go through it and crimp down.

The flex washer goes between the eyelet and the canvas, creating a plastic surface for the sharp edged metal to lay against. This helps keep the eyelet from cutting the fabric.

Boat Cover Snaps: Lift-the-Dot Snaps

Lift the Dot Eyelet Kit Available in Short or Long Prong

Lift the Dot Eyelet Kit Available in Short or Long Prong

Lift the Dot Stud 2 Prong Lift the Dot Stud 2 Prong |

Lift-the-Dot 2 Hole Base Lift-the-Dot 2 Hole Base |

Lift-the-Dot Screw Stud Lift-the-Dot Screw Stud |

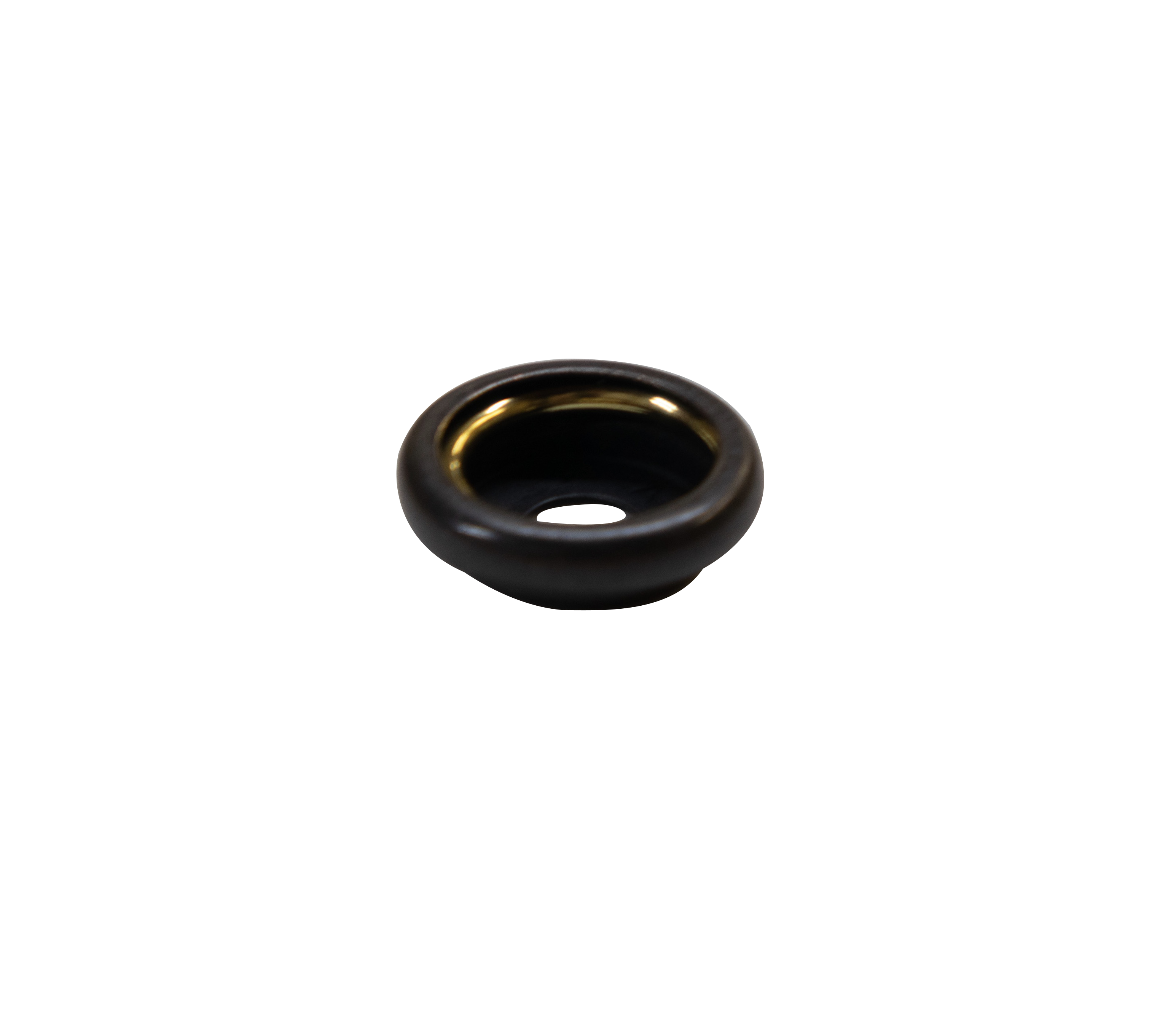

Lift-the-Dot Windshield Snap Lift-the-Dot Windshield Snap |

Lift-the-Dot is the last directional fastener we will talk about here. It also only comes off from one direction. Note the words "Lift-the-Dot" written on the eyelet and also the small dot at the bottom between the words.

This is where you lift this fastener up from, and is the only direction the snap will unsnap from. This snap gets as much if not more use than the curtain fastener by fabricators.

The Lift-The-Dot is a little lower profile than the base of a curtain fastener, making it a little less of a knee banger or toe stub spot on your boat. As you can see, there is also a two screw hole base for added strength, and a windshield clip.

The biggest problem you see with the Lift-The-Dot fastener is the tiny spring inside the eyelet hole sometimes gets sprung and won't fit over top of the stud. If that happens they are easy to replace yourself.

Lubricating this snap twice a year helps keep it working smoothly.

You can install most of these boat cover snaps yourself without too much difficulty.

YKK is a trademark of YKK

Fasnap is a trademark of Fasnap

Lift-the-Dot and Pull-the-Dot are trademarks of DOT Fasteners

Be Sure to Check Out All of Our EZ-Xtend Boat Zipper Products!!

EZ-Xtend

Boat Zippers

EZ-Xtend

Boat Track

EZ-Xtend

Drip Shields

Please come visit me at Cover Girl Marine Canvas & Upholstery to see some of our awesome work!